土工格栅

解决方案概述

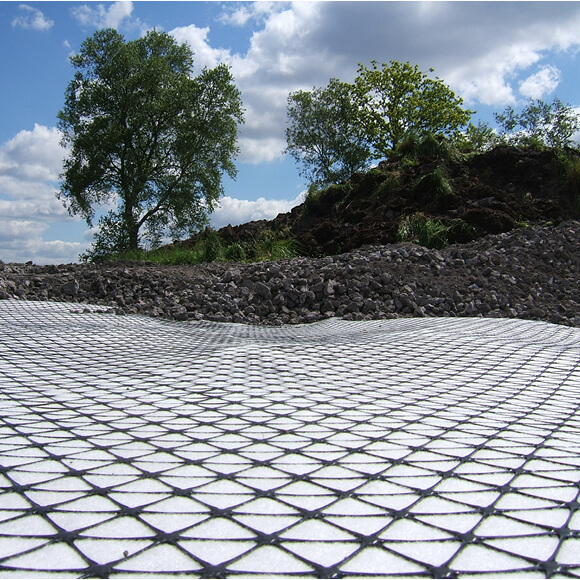

土工格栅包含整体连接的拉伸部分和肋条的二维排列,它们形成网格或网状结构,通常以卷状包装供应。土工格栅由聚合物制成,属于土工合成产品——这是一个广泛的产品分类,包括土工布和土工膜以及其他小类。

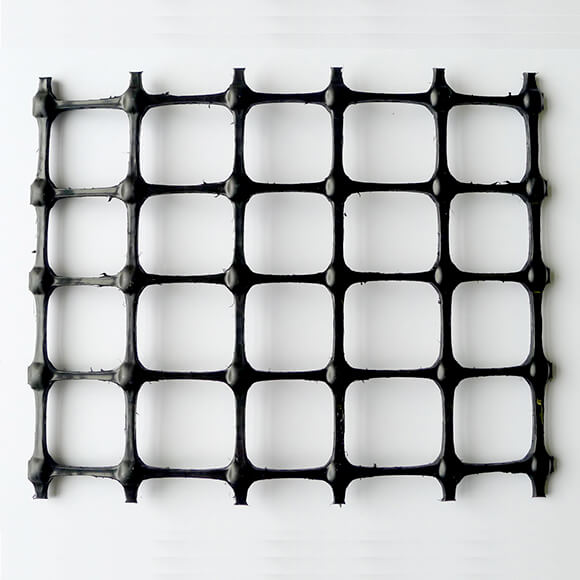

坦萨土工格栅通常由定向高密度聚乙烯 (HDPE) 或聚丙烯 (PP) 制成,具有耐用性、刚度和强度。 肋条之间的连接是一体成型的,具有高强度和结构稳定性。

土工格栅用于解决地基中或地面的土木和岩土工程问题,主要提供加固或加筋功能,以提高土壤或粒料的性能

土工格栅的功能有哪些?

土工格栅主要提供加固或加筋功能,以提高土壤的性能。 它还可分离土壤和粒料层。

土工格栅如何加固土壤?

粒料可以穿过肋条之间的开口或孔径,与土工格栅形成嵌锁。 如果土工格栅足够坚硬,肋骨轮廓足够深并且连接处足够坚固,粒料就会被限制在孔内,从而形成一种新的土工格栅/粒料复合层,具有更高的强度和抗变形能力。

土工格栅如何实现土体加筋?

对于土壤加筋应用,荷载必须在土壤和土工格栅之间转移。 单向土工格栅的横肋具备有效的机理,能够通过邻接而不只是摩擦转移荷载。 土工格栅中的高拉伸荷载由纵向肋条承受。 它们必须能够在结构的整个使用寿命(通常长达 120 年)内承受如此高的负载,需要耐久性以及长期的强度和刚度。

土工格栅比较

土工格栅具备的嵌锁和约束效用取决于其物理特性(平面内刚度、节点接合强度、肋条轮廓)和与粒料的相容性(粒料尺寸和类型)。 具有相同短期 QC 强度的不同土工格栅,可能具有广泛不同的特性,具体取决于制造方法、节点类型、肋材轮廓和使用的聚合物。

对于土壤加筋应用,土工格栅必须具备久经验证的强度和刚度特性以及高耐久性。 土工格栅的长期特性因制造方法和使用的聚合物而异。 坦萨单向土工格栅经认证,可在各种土壤 pH 值和化学侵蚀性环境中使用长达 120 年。

.png)

一般双向土工格栅

- 产品适用两个方向加筋

- 因肋条形状和较低节点强度影响,较低的约束效率,导致性能降低

- 设计参数一般基于小比例模型试验或土工格栅本身的性能

- 主要应用于软基,而应用道路基层通常未经验证

.png)

Tensar® 土工格栅

- 产品适用于力学稳定加固粒料

- 高效的粒料嵌锁约束,提高了地基承载力,限制了表面变形

- 设计参数基于力学稳定层的等比例足尺加速加载行车试验

- 经证实适用于永久道路的基层加固,也适用于软土地基上的道路

.png)

土工格室

- Aggregate or sand fill confined by cell walls to increase bearing capacity. Difficult to achieve compaction within cells

- Complex installation requires more labour and time to open, secure and place first layer. Fill is difficult over weakest soils

- Typically limited to installation over soft soils

.png)

Tensar® Geogrid

- Highly efficient aggregate confinement creates a mechanically stabilised layer with improved bearing capacity. Aggregate compaction is enhanced

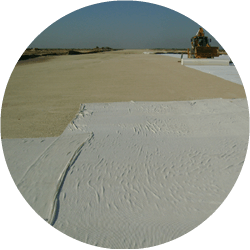

- Installation costs are low. Quick and simple to roll out and commence fill. Over very weak soils access is made possible by ‘snowshoe effect’

- Proven suitability for base stabilisation in permanent roads to increase pavement life as well as for road foundations over weak ground

.png)

Geotextile Reinforcement

- Mobilisation of geotextile strength to reinforce aggregate is limited by friction

- Load support is developed by the tensioned membrane mechanism requiring higher surface deformation to mobilise the reinforcement effect

- Typically limited to installation over soft soils where surface rutting is permissible

.png)

Tensar® Geogrid

- Product design optimised for mechanical stabilisation of aggregates by interlock and confinement

- Highly efficient aggregate confinement by interlock increases bearing capacity and limits surface deformations

- Proven suitability for base stabilisation in permanent roads to increase pavement life as well as for road foundations over weak ground where surface rutting is to be limited

.png)

Chemical Stabilisation

- Large equipment required for treatment. Difficult access over very weak soils. High mobilisation and set up costs limit use to larger area projects

- Limited to use with certain soil types and unsuitable for organic and certain clay soils

- Windblown dust can be an issue during installation. Drainage and hydrology of soil is affected.

.png)

Tensar® Geogrid

- Installation costs are low. Quick and simple to roll out and commence fill. Over very weak soils access is made possible by ‘snowshoe effect’. Suitable for projects of any size

- Mechanically stabilised layers can be used over all soil types including organic soils

- Mechanical stabilisation has minimum environmental impact during installation and when in-place. Suitable for end-of life excavation and disposal

.png)

Non-Stabilised

- Weak soils required to be excavated and disposed off-site, then backfill with suitable materials prior to placement of aggregate layers. Resulting in increased traffic movements, project costs and carbon emissions

- Thicker layers of aggregate required to achieve the same bearing capacity and surface rutting profile. Resulting in higher construction cost, increased time and greater carbon emissions

- Increasing pavement life would require an increase in thickness of the unbound layers, increasing overall costs, materials usage, and carbon emissions

.png)

Tensar® Geogrid

- Allows installation, placement, and compaction of aggregate layers over very weak and variable soils

- Mechanical stabilisation enables reductions in capping layer or subbase thickness over weak or variable soils

- Mechanical stabilisation of unbound layers in permanent roads increases pavement life or enables pavement layer thickness to be reduced for the same life

自由排水隔离屏障

测试和经验表明,当使用适当的级配粒料填充时,坦萨土工格栅具备分离功能。 土工格栅不容易“遮蔽”或堵塞,而土工布用作分隔层时可能会发生这种情况。

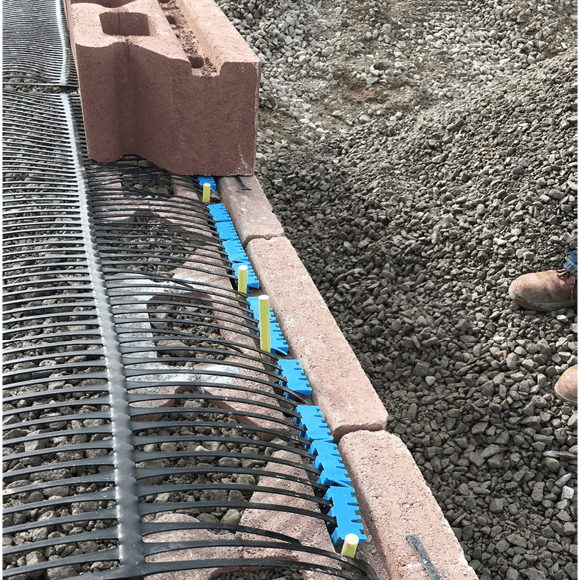

在土工格栅处建造排水渠

为了安装地下公用设施,坦萨土工格栅经常被挖掘和打孔。

.jpg?width=580&height=580&ext=.jpg)